HIT Hafen- und Industrietechnik GmbH offers an automated crane system in a combined storage system. The crane storage system is used for the automated storage, restacking or retrieval of containers. The complete system consists of a crane system with a spreader and the four components: crane control, database, interface and warehouse management.

Crane control

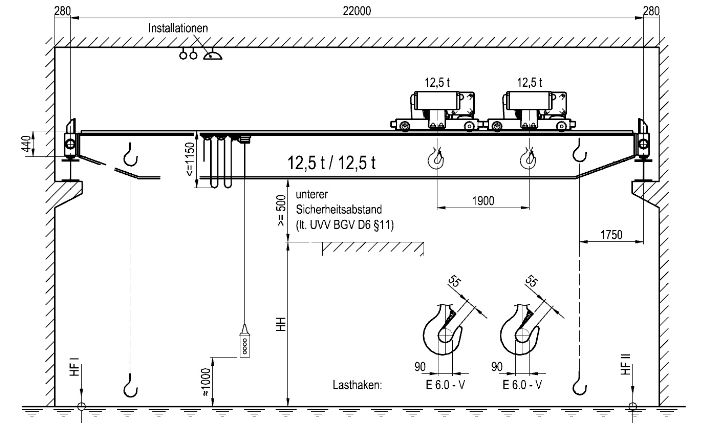

The crane system has a span width of 22000 mm and can stack up to 5 pieces of 20-foot containers on top of each other. A 20-foot spreader is connected to the crane and ensures the safe stacking of the containers.

The crane control system is responsible for controlling the driving gear, crane trolley, hoisting gear and spreader and communicates with the warehouse management system. The control unit can be operated either in automatic or manual mode. In automatic mode, the crane control system receives the work instructions from the warehouse management software. During manual operation, the crane is controlled by a remote control.

The crane control system contains the current container stock (container numbers) of the storage facility and automatically updates the stock when container movements occur. The inventory is compared with the database. This prevents collisions during manual operation and incorrect tracking in the administration.

Database

All information is stored in the database. This information includes the container master data and all data about the stored containers. In addition, all storage or retrieval processes are stored in a history. A redundant system is integrated for data backup.

Interface

An SQL interface enables the exchange of data between the container storage system and the respective internal ERP system (e.g. accounting program). Due to this connection, external processes can be synchronized with the storage/removal movements of the containers. The information can be retrieved either for the entire container movements or specifically for a particular container.

Warehouse management

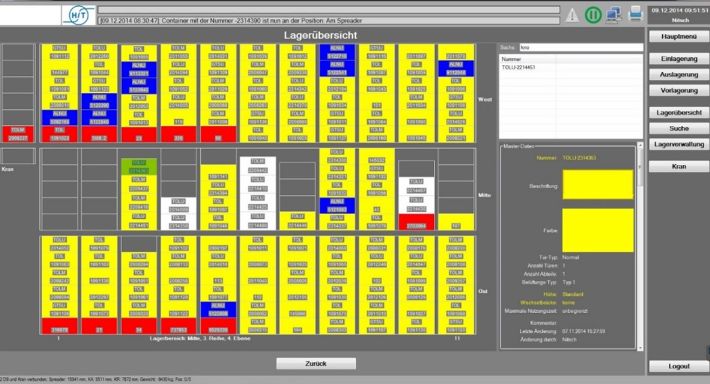

The warehouse management functions as a link between the database, the crane control system and the operator. This last component works by means of a software that supports the storage, restacking or retrieval of containers. Within the software, the stock is synchronized with crane control and the container master data is managed.

In the visualization, you can define the properties of the containers (colored or with images) as well as special zones and storage strategies (e.g. restricted areas or containers with special characteristics to be placed as close to the window as possible). The status of the crane can also be viewed via the warehouse management system and handover/receipt certificates can be printed.

Are you interested in a solution for your system? Then HIT's qualified specialists will be happy to help you at any time!