The machine tool is used for the end machining of SDS-blanks. HIT GmbH has implemented the control technology, the electronic equipment as well as the electronic and mechanical design of the machine.

The system

The system is tasked with the continuous production of rounded grooves and keyway in blanks for percussion drills. The system is connected to a feeding system which feeds and discharges workpieces for the automatic production into the processing machine.

The process

is divided into five sequences:

- Separation of the workpieces in the warehouse

- Checking the storage density in the turnover station using a camera system, turning of the blank if necessary.

- Placement in the feeder for the machine

- Feeding and processing of the workpiece

- Removal and discharge of the finished workpiece

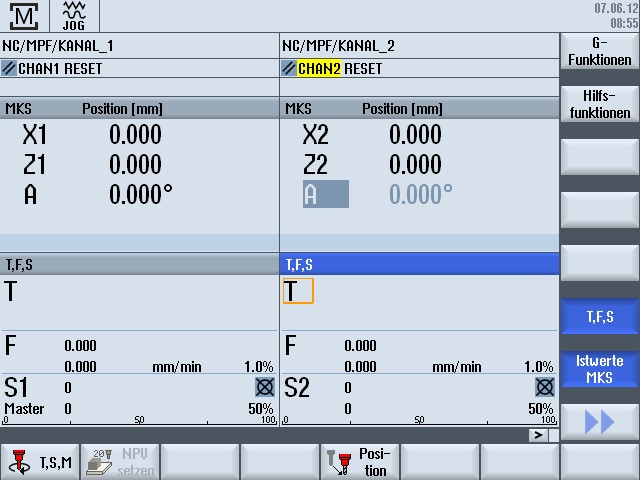

The controls

The Siemens SINUMERIK 840D solution line utilized is a modular and scalable system platform for the controlling of up to 31 axes. This premium CNC is available in different performance variations and can be perfectly adapted to the machine and machining requirements depending on the respective technologies and fields. The modern user interface SINUMERIK Operate ensures a user-friendly and efficient operation on multichannel machines.

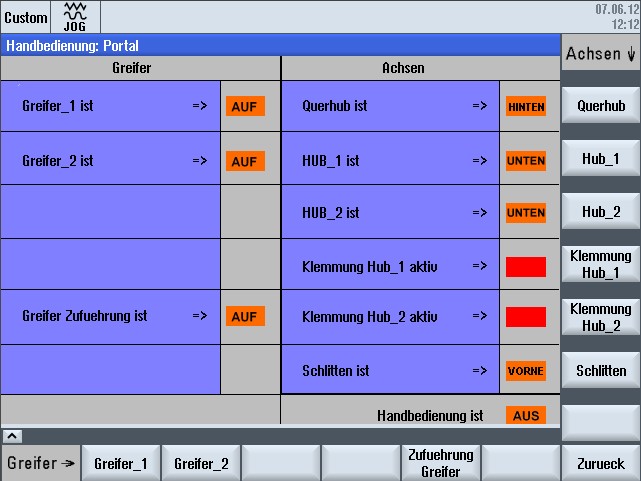

Special functions relating to the system are visualised via especially designed user interfaces for the operator, including status information and operation options.

All non-NC-functions are realised in the integrated PLC. Extensions and adjustments are possible at any time without having to change the parameterized functionality of the machine.

The drives

The NC-axes are controlled via digital SINAMICS drive modules. In connection with SINUMERIK SINAMICS S120 forms the perfect base for modular system and machine design. The standardised digital interface „DRIVE-CLiQ“ from controls to motor does not only allow rapid commissioning via electronic typeplates, but it also simplifies the exchange of components.

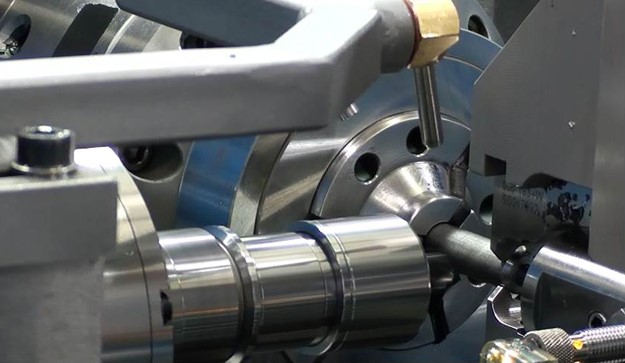

The spindle

The machining tools are driven by an HSC-spindle. Thus a short milling time can be combined with a high surface quality. The time-consuming division into roughing and finishing is not applicable. A water cooling system has been integrated to keep the temperature stable.

The result

High-precision engineered volume components and individual components by a fully-automated facility in continuous operation.

Why HIT?

HIT successfully completed this project. A clear user interface was designed for the operators and a good system and software structure was created for the service team. From the very beginning, the system proved its reliability. These features have increased the failsafe performance and the productivity of the system.