Container crane

The container crane No. 20076230 is newly-built and is meant to assist two container gantries with the unloading of containers.

Project description

The crane is equipped with a hoisting gear, trolley travel and a travelling gear. The supply occurs via a 20kV three-phase motor-driven cable reel. On the crane there is a 800kVa transformer which transforms the voltage to 400 V. The drives are fed by three phase AC drives for variable speeds. Products from the Siemens Sinamics S120 range are used to achieve this. These are feeder units (SmartLine modules) which supply a DC link. This link is in turn attached to inverters (motor modules) which feed the AC asynchronous motors.

Crane Management System (CMS)

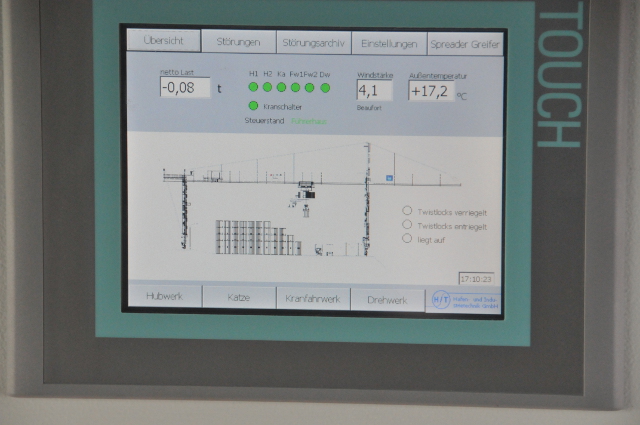

The CMS is represented on two touch panels, type Siemens MP 277 8”. One device is located in the driver’s cabin, the other in the E-house.

The main purpose of these touch panels is the recording of upcoming error messages. Additionally it shows the parameters of the trolley travel, the hoisting gear and the travelling gear. There is an additional touch panel for the error message archive. The error messages are stored in an Excel table. If necessary, these can be downloaded onto a PC.

Monitoring via failsafe PLCs

Another important feature of this system is the safety concept. The PLC is a failsafe Siemens S7-317F. All safety-relevant functions, such as emergency stop signals, emergency limit switches, overload signals etc. are conducted onto failsafe imputs or outputs respectively.

Monitoring by camera

During the crane operation not all areas can be seen. That is why two cameras have been attached to the land-side crane rails. They support the crane driver’s all-round vision. In addition, there is a zoom camera above the spreader so that persons or objects below the crane can be spotted.

Why HIT?

HIT have successfully completed this project. A clear user interface was designed for the operators. From the very beginning, this container gantry has proved its reliability. These features have increased the failsafe performance and the productivity of the system.